Welcome to Our Company

Feed Mixer Machine

100000.00 - 100000.00 INR

Product Details:

- Machine Type Horizontal Mixer

- Speed Mode Variable

- Power Source Electric

- Operating Temperature Ambient

- Phase Single / Three Phase

- Automation Grade Automatic

- Frequency 50 Hz

- Click to View more

X

Feed Mixer Machine Price And Quantity

- 1 Unit

- 100000.00 - 100000.00 INR

Feed Mixer Machine Product Specifications

- Ambient

- Feed Ingredients (Powders & Granules)

- High Mixing Homogeneity, Robust Design

- 5 HP

- Single / Three Phase

- Yes

- Horizontal Mixer

- Manual and Electric

- 2200 x 1200 x 1350 mm

- Grey

- 500-1000 kg/hour

- No

- Electric

- Variable

- Batch Mixer

- 220-240 V

- Animal Feed Mixing

- Rectangular

- 50 Hz

- Free Standing

- Feed Mixer Machine

- Manual and Hopper Feed

- Low

- Heavy-duty Construction, Uniform Mixing

- Mixing

- 480 kg

- Automatic

Feed Mixer Machine Trade Information

- 2 Unit Per Month

- 1 Months

- All India

Product Description

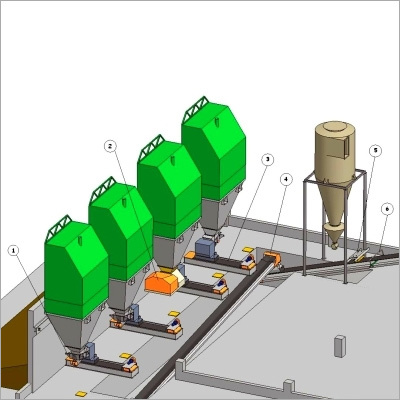

Nirvair Enterprises make available high grade Feed Mixer Machine that is widely known for its higher durability and low maintenance. The offered array of products is examined on the basis of the quality parameter of raw materials and other inputs used for manufacturing. Rest assured about the raw materials used, as we have the most updated technology to examine the quality. We are flexible enough in delivering the products safely and within a stipulated time frame. Due to our spacious and well-maintained storage unit, we keep a large stock in a safe place to ensure complete safety. Our clients can select any payment mode from our online or offline methods. Both are secure, hassle free and ensure the fastest trade with the clients.Efficient Animal Feed Mixing

Engineered for high-volume production, this horizontal mixer streamlines the feed preparation process for poultry, cattle, and aquaculture operations. Its robust alloy steel blades ensure uniform mixing, reducing ingredient segregation and boosting feed quality. The machine delivers swift batches, while heavy-duty construction promises reliability and durability during intensive daily use.

Advanced Safety and Control

With integrated overload protection and an emergency stop system, safety is prioritized throughout operation. The mixer offers both manual and electric control modes for flexible management. Operators benefit from straightforward operation and adjustable mixing speed for precision, making it suitable for varied feed requirements.

Tailored Support and Versatility

Available in single or three-phase configurations, the mixer easily fits diverse operational setups. Onsite and remote assistance ensure rapid support for installation or troubleshooting. Optional castor wheels confer mobility, and the powder-coated exterior provides protection against wear, reinforcing long-term usability.

FAQs of Feed Mixer Machine:

Q: How does the gear motor-driven mechanism enhance feed mixing efficiency?

A: The gear motor-driven system ensures consistent torque and speed, resulting in rapid and uniform mixing of feed powders and granules. This mechanism minimizes downtime and improves batch homogeneity, directly contributing to higher feed quality and reduced mixing time.Q: What is the process for operating the lever-operated discharge door?

A: To discharge mixed feed, the operator simply lifts the lever, allowing the contents to flow out efficiently. This design enables smooth, controlled discharge with minimal spillage, supporting streamlined workflow during batch processing.Q: Where can this feed mixer machine be installed, and what installation type does it support?

A: This batch mixer is designed for free-standing installation and is suitable for feed processing units within poultry, cattle, or aquaculture farms and factories. Its fixed structure with optional castor wheels offers flexibility in placement and relocation within the facility.Q: What safety features are included with the mixer machine during usage?

A: The machine is equipped with overload protection and an emergency stop button. These features help safeguard operators and equipment by automatically halting operations in hazardous conditions, ensuring a secure working environment.Q: When should maintenance or service support be sought for this mixer?

A: Routine maintenance such as checking blades, cleaning the hopper, and monitoring motor performance should be performed regularly. The manufacturer provides onsite and remote assistance for installation, troubleshooting, and any service requirements, ensuring minimal downtime.Q: What are the benefits of using a powder-coated, alloy steel blade mixer?

A: The powder-coated surface resists corrosion and wear, prolonging machine life. Alloy steel blades deliver high mixing homogeneity, ensuring all feed ingredients are thoroughly and evenly blended, improving overall feed consistency and nutritional value.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese